Award-winning PDF software

Form 8379 Online Palm Bay Florida: What You Should Know

However, the process for converting woody fibers into a usable fiber has been elusive — until now. This article explains how the process has been changed, allowing the production of usable hemp fiber products. The process began in the 1960s, when an American named Eugene J. Selznick discovered hemp oil and a way to extract it from the seeds of the Cannabis sativa plant. Selznick began patenting methods for extracting the oil, but his efforts never got past the concept stage, even though they were proven technically correct many years later. This article will explain an innovative, environmentally friendly, and highly cost-effective method for producing hemp fibers. It will give practical methods to produce hemp for commercial purposes, beginning with the extraction of essential oils from plant material, followed by mechanical fiber production, making the hemp materials far more cost-competitive than those made from wood and agricultural crops. Hemp Fibers in a bottle The process by which the oil and its soluble fibers can be extracted from seeds is remarkably simple: the seeds are soaked in water for 15 or 20 hours, then ground into a fine powder and then mixed with glycerine or vegetable glycerin. This is then pumped into an industrial processing plant where the process is applied to the leaves. After passing the plant through an industrial sieve containing a filter for sand, the hemp seed mixture is separated into a fine grain and a large coarse grain. The coarse grain is then further ground into hemp oil. The hemp oil is then pumped into industrial processing plants where the oil separates into the fine grain and large coarse grain. To separate the fine and large fibers from the leaves, a machine called a sludge-filtration plant takes advantage of the cellulose in the leaf to prevent water retention. Water is pumped through the sludge-filtration plant until all the cellulose is extracted, leaving behind only fine fibers. Since the liquid leaves of the plant are not dried, the fibers will remain in the sludge while the leaves settle out. From here, the fibers can be pumped through a machine called an ion-exchange matrix, which extracts the water and solids and turns them into an ion-exchange resin, which, in turn, is separated into fine and large fibers. The finished fibers are processed through filtration again, but instead of using sieve filters, the fibers are separated by using cellulose filtration.

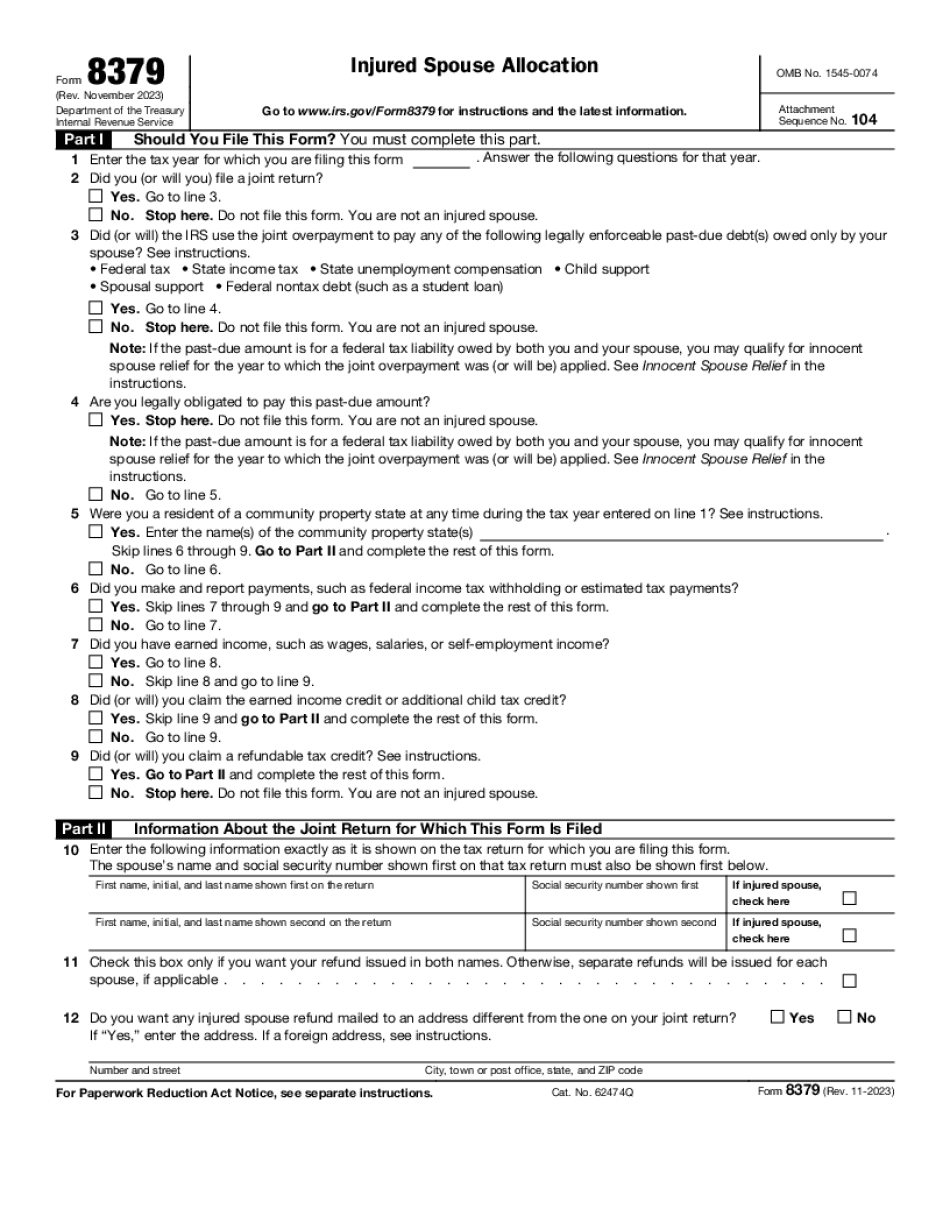

Online methods assist you to arrange your doc management and supercharge the productiveness within your workflow. Go along with the short guideline to be able to complete Form 8379 Online Palm Bay Florida, keep away from glitches and furnish it inside a timely method:

How to complete a Form 8379 Online Palm Bay Florida?

- On the web site along with the sort, click Commence Now and go to your editor.

- Use the clues to complete the suitable fields.

- Include your personal info and contact data.

- Make certainly that you simply enter right knowledge and numbers in ideal fields.

- Carefully verify the articles from the type in addition as grammar and spelling.

- Refer to aid portion for those who have any queries or tackle our Assistance team.

- Put an digital signature on your Form 8379 Online Palm Bay Florida aided by the enable of Indicator Instrument.

- Once the form is completed, push Finished.

- Distribute the all set variety by means of e-mail or fax, print it out or help save on the product.

PDF editor allows you to make adjustments with your Form 8379 Online Palm Bay Florida from any world-wide-web connected equipment, personalize it in line with your requirements, indication it electronically and distribute in several methods.